The expected lifespan of Low-Temperature Co-Fired Ceramic (LTCC) filter in harsh operating conditions depends on several factors, including environmental stressors, electrical load, and material robustness. Here’s a general assessment:

Key Factors Affecting LTCC Filter Lifespan in Harsh Conditions:

1. Temperature Extremes

-

LTCC filters typically operate in 55°C to +125°C ranges.

-

Prolonged exposure to >150°C can degrade materials, reducing lifespan.

-

Thermal cycling (repeated heating/cooling) may cause cracking or delamination.

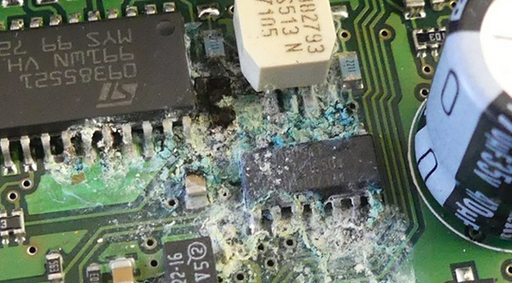

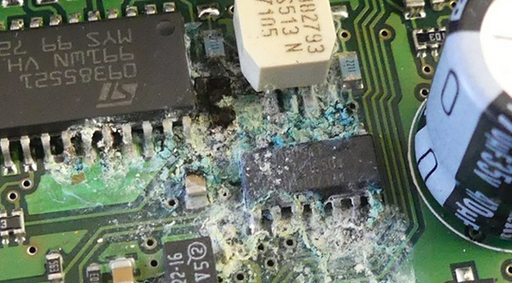

2. Humidity & Corrosion

-

LTCC materials are generally moisture-resistant, but harsh salt fog or acidic environments can corrode electrodes.

-

Hermetic sealing or conformal coatings can extend lifespan.

3. Mechanical Stress & Vibration

-

LTCC is brittle, excessive shock/vibration may cause microfractures.

-

Proper mounting and shock absorption help mitigate this.

4. Electrical Stress

-

High power RF signals or voltage surges can accelerate aging.

-

Operating near maximum rated power may reduce longevity.

5. Frequency of Use

-

Continuous high-frequency operation may cause gradual performance degradation.

Estimated Lifespan in Harsh Conditions:

-

Standard Conditions: 10–20 years (typical for LTCC components).

-

Harsh Conditions (high temp, humidity, vibration): 5–10 years, depending on mitigation strategies.

-

Extreme Conditions : 3–7 years, with possible derating or redundancy.

Mitigation Strategies to Extend Lifespan:

-

Use hermetic packaging for moisture resistance.

-

Apply thermal management (heat sinks, airflow).

-

Ensure mechanical stabilization (damping, secure mounting).

-

Operate below maximum power/voltage ratings.

-

Select high-reliability LTCC formulations (e.g., DuPont 951, Heraeus HTCC/LTCC blends).

Yun Micro, as the professional manufacturer of rf passive components, can offer the cavity filters up 40GHz,which include band pass filter, low pass filter, high pass filter, band stop filter.

Welcome to contact us: liyong@blmicrowave.com